Laser Plastic Welding

Total Solutions for Laser Welding and Joining of Polymers

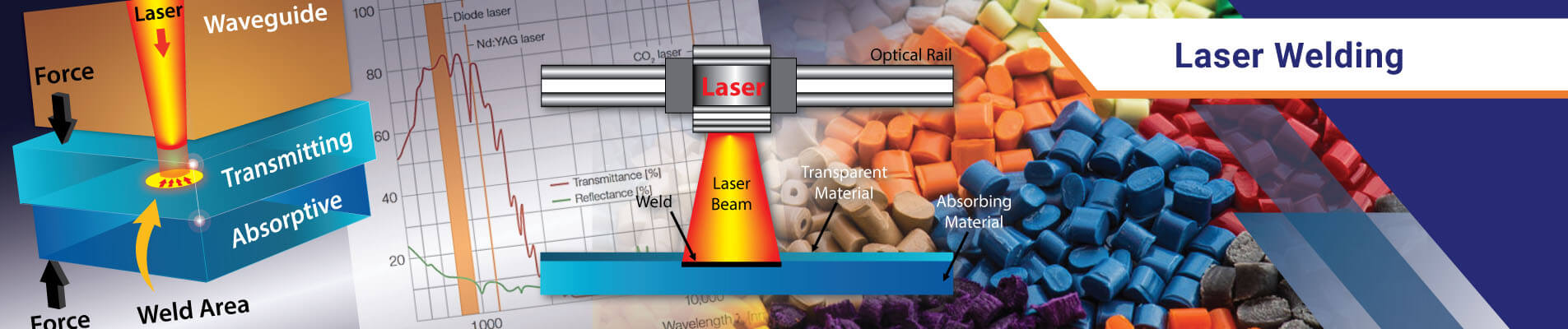

Laser Welding to join thermoplastics can be achieved using two different heating methods: surface heating, and through transmission heating. Through transmission heating is sometimes termed “Through Transmission Laser Welding” (TTLW) or “Through Transmission Infrared Welding” (TTIr). Laser welding is one of the best processes to achieve hermetically sealed, gas-tight welds. Surface heating can be accomplished by expanding the laser beam and simultaneously heating the surfaces of both parts using mirrors. It’s also possible to use a laser line beam or laser spot with a scanning mirror to rapidly scan and heat the surfaces of the parts.

For through transmission laser heating, one part is transparent to the laser while the second has an additive, like carbon black, to absorb the laser radiation and convert it into heat. Materials with high absorption rates are ideal for the lower part of transmission laser welding since they absorb most of the energy at the weld interface and create a thin, heated surface layer that is ideal for welding. Some optically clear plastics & films can be welded using longer wavelengths in the range of 1500nm to about 2000nm (2-micron) to produce bulk heating.

Carbon Black Selection

For Successful Transmission Through Laser Welding and Joining

Laser welding is used in a wide range of applications to join thermoplastics because it is a noncontact heating method with short cycle times and lower cost. For both surface heating and through transmission heating, carbon black is the most frequently used colorant. It was found that carbon black types with low particle aggregation and distribution were most effective for laser heating.

Experiments with laser line beam scanning showed that a slight tilt in the laser head could produce different heating when traveling forward as compared to backward. For dissimilar polymer joining, it was found that surface texturing increased the adhesion joint area and the amount of mechanical interlocking, resulting in superior joints.

Plastics Laser Welding Services – SABREEN Solutions

SABREEN’s expert knowledge guarantees plastics laser welding excellence. Over 40 years of experience in the fields of laser additives, polymers and colorants, laser sources, systems design, manufacture and integration, regulatory compliance, and injection molding processes.

- Custom laser color match formulations and compounds, regulatory compliance, prototype samples–masterbatch, pre-compounded materials (pre-color), laser laminates.

- Optimization of laser source, wave guide properties, optics, and beam delivery specific to polymer-colorant matrix. NIR wavelength 1060-1080nm Ytterbium fiber, Vanadate, frequency-doubled 532nm Green or UV 355nm.

- Laser equipment systems design, turnkey systems integration & training, machine vision, custom HMI, process documentation.

- On-site problem-solving (any global location), laser process analysis and system optimization, custom vectorized artwork.

- Laser safety certification, complete application including design and CDRH Class 1 enclosure, laser safety officer (LSO) for internal audits.

- Plastics injection molding and analytical analysis, mold flow, additive-colorant dispersion/distribution.

Total Solutions

Polymer-colorant material science, injection molding, laser technology, systems integration and training. Unique formulations are engineered to cover a broad spectrum of laser technologies. Our selection of laser sources also enables our clients to mark/engrave metals, as often required.

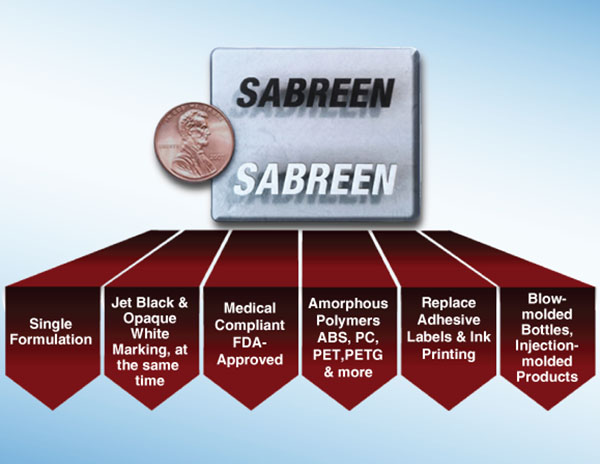

Laser Additives

Game-changing additives produce jet black, light-colored and custom color contrast. Additives are blended with polymers during molding operations as color concentrate masterbatch or precompounded materials. Low dosing does not affect any polymeric properties. FDA/EFSA-approved versions available.

NEW Breakthrough Technology

New single formulation additive produces jet black and opaque white laser marking contrast at the same time. Ideal technology for label replacement and ink printing on blow molded bottles and injection molded products.

Interior Automotive Lever

Award Winning Employee Smart Badge, RFID.

Automotive cap-less fuel filler

Medical tubing, FDA compliant for invasive surgical procedures. On-the-fly laser marking replaces ink printing.

Jet Black laser marking contrast. New additive is FDA compliant. Doesnotcontain heavy metal antimony-tin oxide/trioxide. Ideal for animals.

On-the-fly laser marking of linerless beverage closures. FDA compliant additive. Marking speed of 2,000 closures per min. HDPE, PE, Polypropylene, more.

Polyolefin medical syringes, FDA-approved laser additive, replaces pad printing

Daytime/night-time laser marking, waterbase coatings

Laser marking surface reactions

Special laser additives incorporated into photo/ID cards for product security

Laser additive breakthrough

SABREEN Invention

Laser Marking Terminology

“Laser Marking” of plastics is a noncontact digital process whereby indelible information is applied onto a target substrate surface with minimal material penetration. Information is typically in the form of alphanumeric text, symbols, graphics, logos, schematics, barcodes, machine vision codes, etc. Beam-steered Ytterbium fiber lasers (and predecessor Nd:YAG lasers arc-lamp and diode-pumped) operating at 1060-1080nm (near-infrared) possess ideal waveguide properties specific to their emission wavelength & power performance (peak & average power). Flying optics is an alternative method for part marking. Select colors of specific polymeric materials can also be marked using shorter wavelengths 532nm (frequency-doubled) and UV 355nm.

The basic mechanism of beam-steered laser marking, using a wavelength of 1060-1080nm, is to irradiate the polymer with a high-energy radiation source. The radiant energy is absorbed locally by the material and converted to thermal energy. The thermal energy, in turn, induces reactions in the material substrate. Several types of reactions are possible using the near-IR wavelength region, including charring, ablation, and chemical change. Depending upon the desired marking contrast results, vastly different chemistries and laser system parameters can be selected to achieve the preferred type of reaction.

Carbonization or charring reaction occurs when the energy absorbed raises the local temperature of the material surrounding the absorption site to a sufficiently high level that thermal degradation of the polymer is caused. In the presence of oxygen, this results in the burning of the polymer, but within the workpiece, a limited oxygen supply causes a charring of the polymer to form a black mark. The darkness of the mark is dependent on the energy absorbed as well as the material’s thermal degradation pathway.

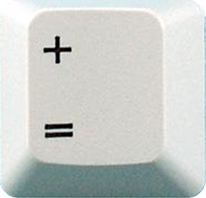

Example – ABS Computer Keycaps

Laser Etching of plastics (also known as “ablation”) is a noncontact digital process whereby a laser beam removes material from the substrate surface by vaporization or melting, with minimal penetration. The depth of a laser etch is usually no more than 0.001”.

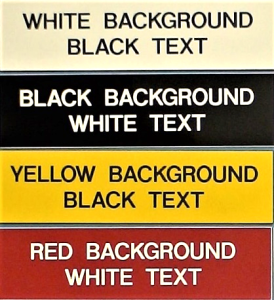

Example – Daytime/night-time Automotive Buttons

The day/night process application is to remove layers of material to expose a specific color layer. The example demonstrates a white base coating that is over-coated with one or more layers of black coating. The base polymer is typically clear Polycarbonate or ABS, both amorphous polymers to transmit (back) light from LED sources. Deeper marks into the substrate would be considered “engraving” into the material, not just etching the surface.

Laser Engraving is a deeper process than laser etching and laser marking. CW CO2 lasers operating at 10.6 ?m wavelength are typically utilized for direct colorless engraving of polymers. Another engraving application is the multi-layer engraving of selective color layers (core-color and surface color), e.g., nametags, labels, and signage.

Power density is a function of focused laser spot size (laser power per unit area, watts/cm2). This is different than the raw output power of the laser. Focused laser spot size for any given focal length lens and laser wavelength is a function of laser beam divergence, which is controlled by laser configuration, mode selecting aperture size, and upcollimator (beam expander) magnification.

Pulse repetition rate (via acousto-optic Q-switch) and peak power density are critical parameters in forming the mark and achieving the optimal contrast and speed. High peak power at low frequency increases the surface temperature rapidly, vaporizing the material while conducting minimal heat into the substrate. As the pulse repetition increases, a lower peak power produces minimal vaporization but creates more heat. Beam velocity (speed of the laser beam across the work surface) is also a critical factor.

Laser additives improve the degree of contrast, which can be further intensified by changing the laser setup parameters. Polymers possess inherent characteristics to yield “dark-colored” or “light-colored” marking contrast. Some colorant compounds containing low amounts of Titanium dioxide (TiO2) and carbon black may also absorb laser light and, in some instances, improve the marking contrast. Each polymer grade, even within the same polymeric family, can produce different results. Additive formulations cannot be toxic or adversely affect the product’s appearance and physical or functional properties.

Compared to ink printing processes (pad/screen printing and inkjet), laser additives are cost-saving and demonstrate 15 percent (or greater) faster marking speeds versus non-optimized material formulations. Laser additives are supplied in pellet granulate and powder form. Granulate products can be blended directly with the polymer resin, while powder forms are converted to masterbatch. Most easily are dispersed in polymers. Based on the additive and polymer, the loading concentration level by weight (in the final part) ranges from 0.01 percent to 4.0 percent.

Both granulate and powder forms can be blended into precompounded color material or color concentrate. The selection of which additive to incorporate depends upon the polymer composition, substrate color, desired marking contrast color, and end-use certification requirements. Some additives contain mixtures of antimony-doped tin oxide and antimony trioxide that can impart a “grayish” tint to the natural (uncolored) substrate opacity. Other additives can contain aluminum particles, mixed metal oxides, and proprietary compounds. Color adjustments are made using pigments and dyes to achieve the final colormatch appearance.

As commercially supplied, specific additives (also used for laser welding) have received FDA approval for food contact and food packaging use under conditions A-H of 21 CFR 178.3297 Colorant for Polymers. For the European Union, there are similar compliance statements. Certification conditions are specific for polymer type, loading level threshold, and direct or indirect contact. Further qualification of FDA-approved additives blended into a “final part” can achieve biocompatibility of medical devices (reference International Standard ISO-10993).

Achieving Faster Marking Speeds

The time required to mark a part is a function of the polymeric substrate, the number of vector lines drawn, and how fast the laser beam/galvanometer scan head draws all of the lines. Laser software and the type of vector fill, unidirectional, bidirectional or serpentine, can also effect the marking time.

New independent studies are showing that statistically significant faster marking speeds are achievable by incorporating laser additive formulations at very low concentration levels, typically 0.01% to 2.0%.

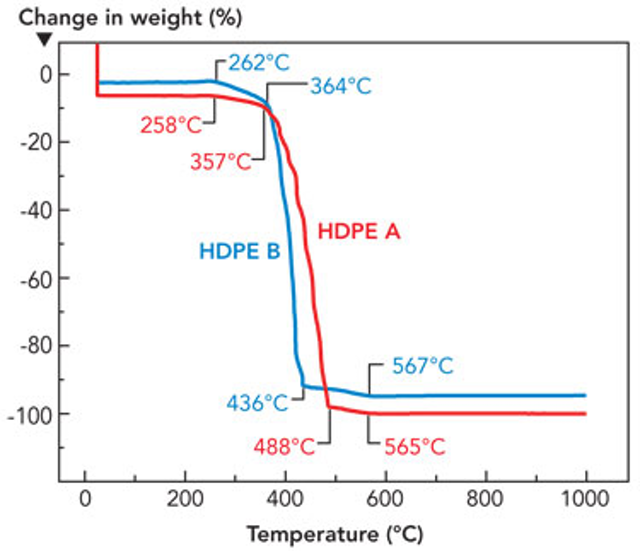

The figure to the right shows a thermal gravimetric analyses (TGA) plot for two high density polyethylenes. The two polymers exhibit different temperatures of thermal degradation – the process that creates the laser mark. The higher-temperature polymer will require more laser energy, lower marking speeds, or more absorbing additives to achieve the same mark appearance.

Primary Molding Operations

Following the completion of the “laser optimized” material science (which includes establishing the optimal contrast, chroma color, and laser setup parameters), the next step is to conduct a molding trial using the actual production mold tool at the proper letdown ratio. This step is critical to ensure uniform dispersion and distribution of the laser optimized color matrix. After molding, the actual product parts are laser marked to confirm the original results.

One technique is to program the beam-steered laser to continuously mark (scan) the entire product surface. The figure to the left (left to right) injection molded writing pen showing gold-on-black chroma laser marking (left), middle two pictures showing poor chroma distribution, and far-right showing excellent uniform distribution.

Processing Considerations

During the laser additive loading/colormatch chemistry, it is not uncommon for a finished product to contain less laser additive than the calculated amount. This problem almost always relates to non-uniform distribution during extrusion or molding. Simple adjustments to the molding machine, such as increasing the back pressure and screw rotation speed, will resolve most issues. Homogeneous distribution/dispersion of laser additives throughout each part is critical to achieving optimal marking performance. For extrusion, injection molding, and thermoforming operations, precolor compounded materials versus color concentrate yields better uniformity. Hand-mixing should be avoided. Mold flow and gate type/location are important factors.

Not all lasers are created equal! The hardware and software components a laser manufacturer incorporates into its systems make significant differences in marking quality, speed, and versatility. When procuring laser systems, it is important to remember there is not a single universal solution. Each application is unique relative to the plastic substrate composition and color, marking quality, speed, laser efficiency, contrast (dark-on-light, light-on-dark, or color), and total system costs.

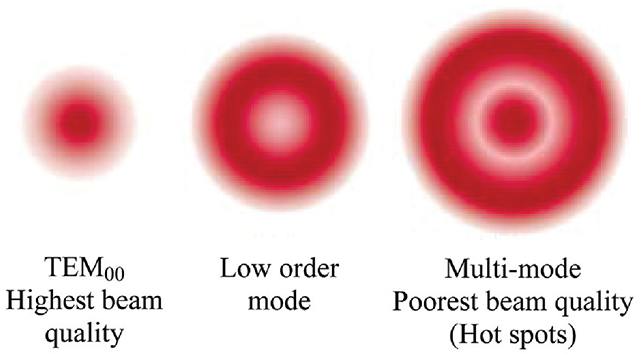

Beam quality output mode refers to the energy distribution within the laser beam and is critical to marking performance. Lasers can be supplied by manufacturers as multimode (MM), TEM00 (Transverse Electromagnetic Mode), or anything in between, including Low-Order Mode (LOM). These output modes relate to factors including the beam divergence and power distribution across the diameter of the laser beam. A TEM00 laser beam can be focused to the smallest size spot that the focusing optics permit and the energy distribution in a TEM00 laser beam is most intense at its center and tapers off uniformly from its center to its edges. TEM00 laser output provides the highest beam quality. Multi-Mode (MM) laser output provides the poorest beam quality.

Reference the figure below. Low-order and TEM00 mode lasers are particularly well suited for high-speed vector marking of single-stroke alphanumerics, filled true-type fonts, and complex graphics because of their ability to achieve a small, focused spot with very high power densities, resulting in a very narrow line with well-defined edges that can be drawn quickly. Most plastics applications are optimal using near TEM00 or TEM00 laser beams.

Power density is a function of focused laser spot size (laser power per unit area, watts/cm2). This is different than the raw output power of the laser. Focused laser spot size for any given focal length lens and laser wavelength is a function of laser beam divergence which is controlled by laser configuration, mode selecting aperture size and upcollimator (beam expander) magnification. Pulse repetition rate (via acousto-optic Q-switch) and peak power density are critical parameters in forming the mark and achieving the optimal contrast and speed.

High peak power at low frequency increases the surface temperature rapidly, vaporizing the material while conducting minimal heat into the substrate. As the pulse repetition increases, a lower peak power produces minimal vaporization but creates more heat. Beam velocity (speed of the laser beam across the work surface) is also a critical factor.

Laser control software is as important as any hardware component in the marking system. Advanced software algorithms enable unprecedented speed. Beam-steered laser markers are sometimes wrongly conceptualized as (desktop) printers. In fact, they are plotters. Rather than placing individual pixels to create alphanumeric letters or graphics, the laser draws lines much like writing with pencil and paper. Regardless of the input file format originally used to create the laser marking objects, all marking is eventually reduced to its most simple form, a list of vector lines to be drawn by the scan head and marked by the laser. Complex input file formats often used by design engineers may not necessarily yield the best (or fastest) vector laser marking. Laser marking equipment systems must be safe and conform to ANSI Z136 standards.

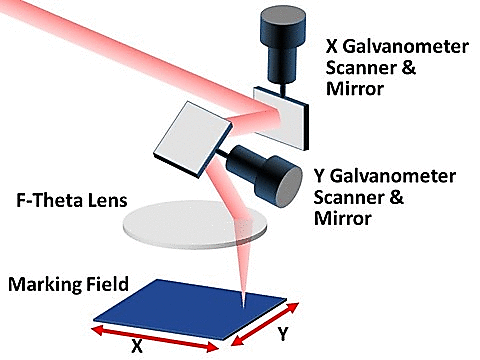

Beam-steered Nd:YAG laser markers (arc lamp and diode light sources) utilize mirrors that are mounted on high-speed computer-controlled galvanometers to direct the laser beam across the surface to be marked, much like writing with pencil and paper.

Each galvanometer, one on the Y-axis and one on the X-axis, provides the beam motion within the marking field. A flat-field lens assembly focuses the laser light to achieve high power density on the substrate surface. The figure to the right shows Optical beam delivery system using computer-controlled galvanometers.

Fundamentally, fiber lasers are different than other solid-state marking lasers. With fiber lasers, the active medium that generates the laser beam is dispersed within a specialized fiber optic cable. In contrast to fiber-delivered lasers, the entire path of the beam is within fiber optic cable all the way to the beam delivery optics.

The advancements in laser technology have been instrumental to the rapid development of the newest generation of FDA-approved laser additives. The emergence of nanosecond Ytterbium Fiber lasers is one of the most significant advancements for marking, welding and cutting. Fundamentally, fiber lasers are different than other solid-state marking lasers. With fiber lasers, the active medium that generates the laser beam is dispersed within a specialized fiber optic cable. In contrast to fiber-delivered lasers, the entire path of the beam is within fiber optic cable all the way to the beam delivery optics.

Fiber lasers yield superior beam quality and brightness compared to Nd:YAG lasers. One metric for beam quality is M2. The smaller the M2 value, the better the beam quality, whereas M2 = 1 is the ideal Gaussian laser beam. A laser with superior beam quality can be focused to a small spot size, which leads to high energy density. Fixed and variable pulse (MOPA) fiber lasers with pulse energy up to 1 mJ and high power density can mark many historically difficult polymers. Vanadate lasers also possess a small M2 value with shorter pulse width than fixed fiber and YAG lasers. Pulse duration influences the degree of heat and carbonization into the material. Short(er) pulse width can be advantageous for sensitive polymeric applications.

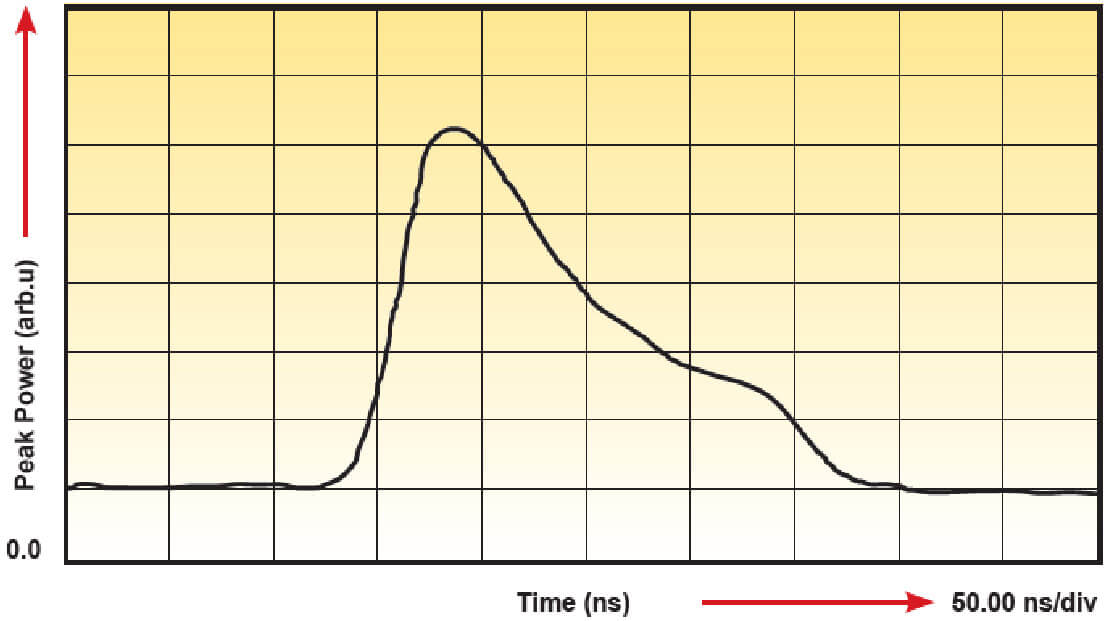

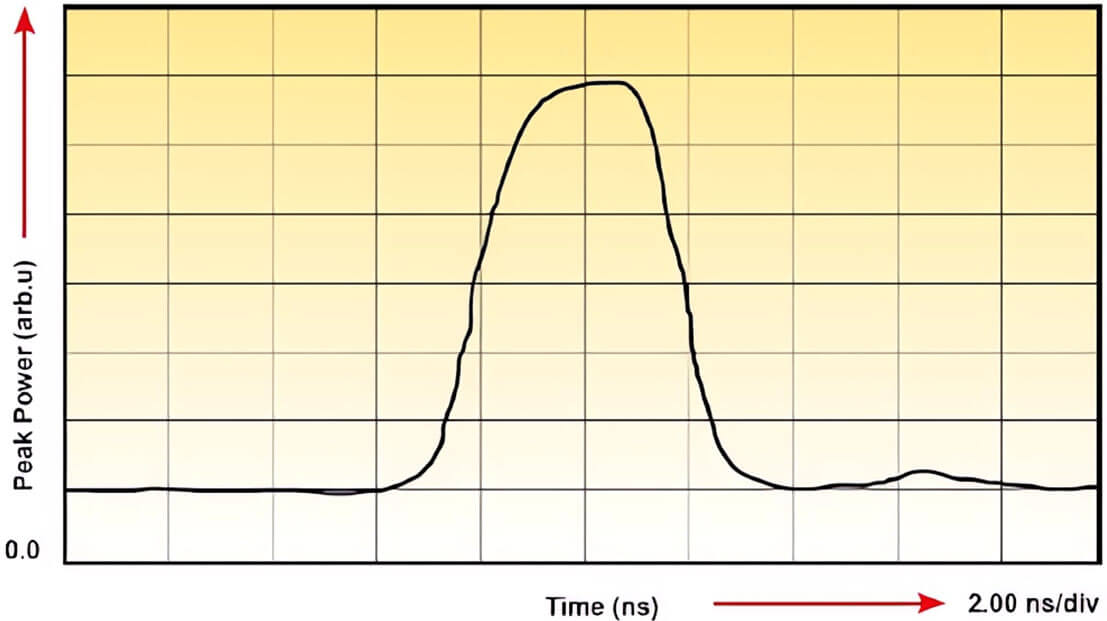

IPG Photonics, a leading developer and manufacturer of high-performance fiber lasers, offers both fixed pulse (sometimes referred to as “Q-switch”) and variable short pulse (MOPA) lasers. Application development is highly specific. The selection of which laser type to integrate is determined by the output characteristics of the laser interacting with the optimized polymer material. Reference the graphs below, representing Temporal Pulse Shapes of Fixed and Variable (MOPA) Pulse Length Ytterbium Fiber Lasers – IPG Photonics.

When setting up a fixed pulse length fiber laser for marking, two inputs must be set.

1) Pulse repetition rate (often referred to as pulse frequency)

2) Pump power in percent (100 percent refers to the maximum possible electrical input to the pump diodes)

When setting up a variable short pulse MOPA fiber laser for marking, three inputs are set.

1) Pulse duration (often referred to as pulse length)

2) Pulse repetition rate (pulse frequency)

3) Pump power in percent (100 percent refers to the maximum possible electrical input to pump diodes)

For both graphs on the previous page, the particular combination of parameter inputs controls the output properties of the laser beam, namely the pulse energy, the peak power (the highest instantaneous peak of the pulse energy, J/pulse duration) and the average power (average power in Watts = pulse energy in joules x pulse repetition rate in Hz).

Pulse repetition rate and peak power density are critical parameters in forming the mark and achieving the optimal contrast and speed. The arithmetic curves of power versus pulse repetition rate are inversely proportional. High peak power at low frequency increases the surface temperature rapidly, vaporizing the material while conducting minimal heat into the substrate. As the pulse repetition increases, a lower peak power produces minimal vaporization, but conducts more heat. Additional contributing factors that influence the marking contrast and quality are, of course, beam velocity and the vector line separation distance.

“On-the-fly” laser marking is performed on molded and extruded products, such as wire/cable, tubes and pipes. Marking speeds for polyolefin synthetic wine corks and undercap promotions on linerless beverage closures are capable of 2,000 pieces per minute for alphanumeric text and graphics. Marking speed is a function of many variables, including polymer type, substrate color, laser additive type and loading level, cable size (weight), laser type and power, software, number of alphanumeric characters, text height, length of text string, space between characters, bar code/ data matrix, logos/graphics, single-stroke or true-type filled fonts, fill direction and continuous or repeating text. Use of the proper formulated additive-colorant will ensure that “power density” at the mark surface is not the limiting factor. Rather, the beam-steered galvanometers will be operating at maximum speed.

Due to the complexity of factors influencing on-the-fly production marking capability, every application must be precisely examined. There are few, if any, rules that can be extrapolated. However, for general purposes, consider the following nylon polymer example: 50-watt fiber laser, 254mm flat field lens, 100 alphanumeric characters, 2mm height, comprising a repeating text string length of 14.68 inches with a marking time of 0.232 seconds. The calculated speed is approximately 315 linear-feet per minute.